Water Proofing Treatment of Roof Slab

In this method polymer modified cementitious slurry coatings are applied over the base concrete. This technique of waterproofing is latest development in the field of waterproofing.

Polymer imparts significant improvement in impermeability.

Polymer modified cementitious slurry has coefficient of expansion very similar to concrete thereby it does not get cracked due to thermal variation of concrete.

Polymer modified cementitious slurry coatings consist of a liquid blend and a dry blend. The liquid blend consists of the polymer, liquid additives, and clean water. Dry blend consists of locally available Portland cement and aggregates.

These blends are mixed in specified ratio generally 2:1 (cement: polymer) by weight and applied by brush on a prepared clean surface.

Generally, two coats are provided. However, manufacturer’s recommendations should be followed in this regard.

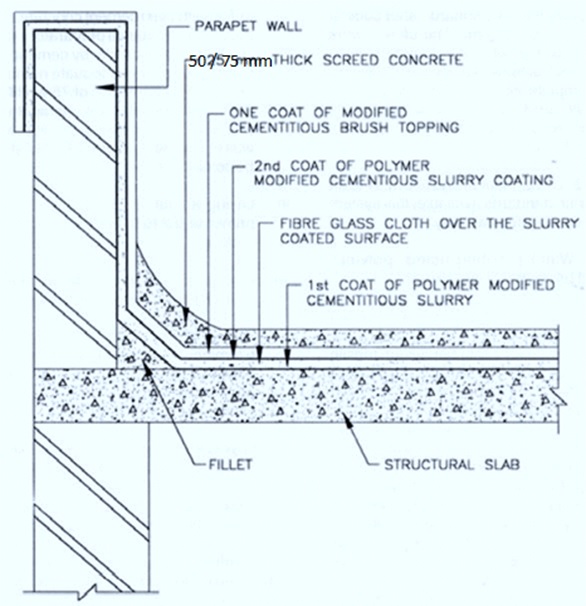

To impart more flexibility, it is desirable to use some reinforcement like fibre glass cloth sandwiched between two coats.

This coating should be covered by screed concrete to protect it against physical damage.

This system can be used over new as well as old roofs.

Following steps are involved in application of this system.

i) Preparation of roof surface:

The surface shall be cleaned to remove all dust, foreign matters, lose materials or any other deposits of contamination. Cracks and depression shall be filled up by fillers. Prepared surface shall be thoroughly pre wetted for one hour.

ii) Preparation of polymer modified cementitious slurry:

Dry blend and liquid blend shall be mix into the desired ratio as per recommendation of supplier. The mix shall be stirred thoroughly, until no bubbles remain in the mix. Any lump found in mix shall be removed.

iii) Application of first coat:

First coat of polymer modified cementitious slurry shall be applied by brush on wet cleaned surface.

iv) Laying fibre glass cloth:

Subsequently, fibre glass cloth shall be laid over first coat of polymer modified cementitious slurry.

v) Application of second coat:

Second coat of polymer modified cementitious slurry shall be laid over fibre glass cloth in a criss-cross direction to the previous coat.

The minimum thickness of the dry film of complete application should not be less than as recommended by manufacturer’s specification

vi) Application of brush topping:

Polymer modified cementitious brush topping shall be applied over second coat of polymer modified coating.

vii) Application of screed concrete:

On brush topping, screed concrete, admixed with suitable integral water proofing compound 25 to 40mm thick to a min. slope of 1 in 100 (or as per drawing), with aggregate size down 10mm with maximum water cement ratio 0.45, shall be laid.

Above system may slightly differ from case to case depending upon the instruction of supplier of water proofing system.

viii) At Junction of parapet wall and roof

The fillet (angular or concave, not convex) of adequate size should be provided all along the junction of parapet wall with roof.

Water proofing system should be extended from roof to parapet wall for a minimum height of 150 mm with a chase.

Note:

Since there is no relevant Indian or any other standard available, this system needs to be adopted carefully. Work should be carried out as per manufacturers/ supplier’s instructions. Users are advised to collect complete literature from manufacturer and study carefully prior to application of treatment

What are the ingredients of polymer coating please share the details. Thanks

Can you recommend a suitable brand of polymer modified cementitious material for water proofing the roof slab. Regards